The Dynamic Correlation Integration Real Time Optimization technique(DCIO)

Founded in 1986 by Dr. Jian Wang, board Chairman of the company, the technology of Dynamic Correlation Integration Optimization(DCIO)was based on random theory of process, and optimizes petrochemical units in real time. It utilizes the

fluctuant characteristics of optimizing objective and process variables, calculates the dynamic correlation integration of them, and determines direction and value of optimizing. Through 25 years’ period of experience, the DCIO has applied in about 20 petrochemical units in China which mostly achieved a result of 0.5-1.0% increase in yield rate of main products, and brought more values to customers.

In the process of production, on-line tuning the key operating conditions of the process, maximizing the objective functions, such as yield and benefit, are the task of the Real Time Optimization

Traditional optimization is based on a mathematical model,which is built by means of mechanism of chemical process, or the statistic data from operation or testing. If raw material changes and/or production units reform, the model has to be rebuilt.

On the contrary, the Dynamic Correlation Integration Optimization (DCIO) makes use of the dynamic information in optimizing variables and objectives, calculates the Dynamic Correlation Integration (DCI) of them. By analyzing the matrix of DCI, the direction and value of the optimized variables manipulating are obtained, and the optimized objective will be carried out on-line at last.

High lights of the DCIO and pre-conditions of its application

The correlation integration optimization technology has following features:

- Unnecessary to pre-build static and dynamic process models.

- An extremely strong self-adapting capability to automatically trace the

optimum when such conditions like raw material and equipment, etc. change.

- Operating by means of natural fluctuation in the process, no need of additional

test signals to it, and reducing disturbance to the process operation to the lowest level.

Any process may apply the DCIO technology if they had following conditions;

- Continuous manufacturing.

- The optimized objective can be measured or calculated on line.

- DCS controlled

Series of products

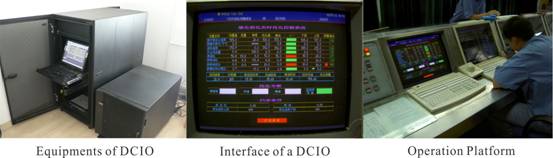

The company has four series and dozens of varieties of products, including Dynamic Correlation Integration Optimizer, DCIO Express for FCC, DCIO Express for dewaxing, and General Soft Sensor,which could be used in petrochemical and other industries.

Name |

Application field |

Functions |

DCIO |

Petrochemical |

Real-time optimizing for continuous process |

DCIO for FCC |

Refining |

Maximizing yield rate of LPG、gasoline、diesel、liquid and benefit in real time |

DCIO for Dewaxing |

Refining |

Maximizing yield rate of waxing oil in real time |

GSS |

Petrochemical |

Measuring the unable or difficult measured varieties |

A typical case

The real-time optimizing system for MIP-CGP FCC unit in Qingdao Refinery

A report of the RTO result (Abstract)

1、Brief introduction of the RTO of MIP-CGP FCC

The real-time optimizing of No.2 FCC unit in Qingdao Refinery, SINOPEC, adopted the DCIO technique of Beijing OptimiPro Control Tech Co.,Ltd. in 2007, and it optimizes the main operating conditions of the reactor – regenerator system of the unit.

Five target of optimizing could be selected, including liquid hydrocarbon yield, gasoline yield, diesel yield, total liquid yield, and benefit. At present, the RTO takes benefit of the unit as the optimizing target. In the RTO, five on-line optimized varieties are:

1.Temperature of first reaction

2.Flow of pre-lifting steam

3.Feed temperature

4.Catalyst inventory in the second reactor

5.Flow of fresh catalysts

The benefit refers to economic income when refining one ton of oil.

2、Performance evaluation of the DCIO

To evaluate the effect of the DCIO, we arranged a test, and got results as follows:

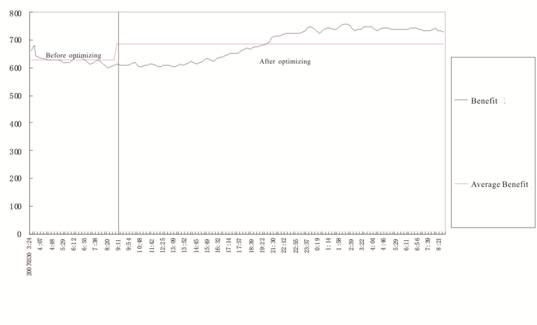

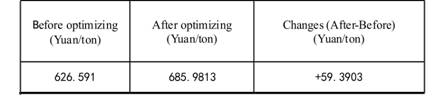

A historical trend in the testing is shown in Figure 1.

The changes in benefit after optimization are shown in Table 1.

It can be seen from the test results that the total benefit of the unit has increased after DCIO is used.

3、Evaluation of DCIO for a long term operation

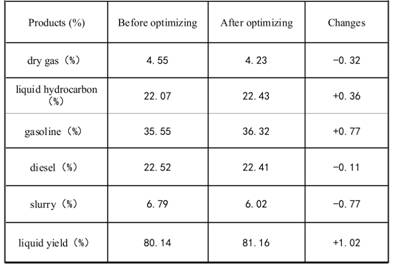

To evaluation the operation of the DCIO for a long term operation, we compared the statistical balance of materials for a period of 3 months before and after the DCIO was used. The result, the comparison of yields of products before and after optimization, is shown in the Table 2.

It could be seen from a long term and continuous optimizing operation, the DCIO is very effective, and the benefit of the unit is increased.

According to the statistical balance data from the user, the DCIO could obtain a benefit of about 80 million Yuan a year.

Independent intellectual property rights

The company has regarded innovation and protection of independent intellectual property rights as a foundation stone of the firm, and invested much manpower and capital in the research and development, and therefore formed an intact system of intellectual rights. The company is now able to afford customers independently with a whole package of techniques without any authorization from other companies.

|